Variable Frequency Drives (VFDs) are one of our best allies for managing energy efficiency in motor control.

Need Variable Frequency Drives For Your Project?

Get VFDs QuoteSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsUnderstanding Variable Frequency Drives in Controlling Motor Speed

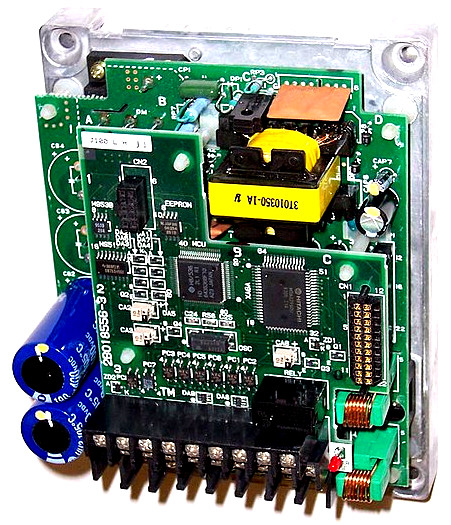

VFDs are high-tech electrical devices that save energy and increase production by regulating an electric motor’s speed and torque. VFD’s save energy by adjusting the power supply to the motor’s frequency and voltage, giving you exact control over how quickly the motor rotates. Because they can change the motor speed on demand, VFDs are adaptable in a variety of industrial processes. Looking for a reconditioned VFD?

The options are endless when it comes to how VFD’s save energy and increase production. Variable Frequency Drives are useful in almost every aspect of industrial production, including pumping systems, HVAC units, conveyor belts, and manufacturing gear. Their versatility and efficiency make them necessary tools for modern manufacturing plants, warehouses, and industrial facilities.

One of the major advantages of VFD technology is its ability to improve energy efficiency, which means significant savings for you. Traditional motor control methods can be wasteful since they release excess energy as heat. However, using VFDs, you can improve energy use by adjusting motor speed to the required workload. In other words, VFDs reduce energy waste and operating expenses by decreasing motor speed during low demand periods.

The advantages go beyond energy savings. They improve your performance by accurately managing motor speed and torque, resulting in smoother operation and less wear and tear on your mechanical components. This translates to longer equipment life and fewer maintenance requirements, which adds to your cost savings and operational efficiency.

VFDs are driving change and innovation for energy efficiency across industrial sectors.

VFDs Save Energy and Increase Production Across Industry Sectors

VFDs in Pumping Systems Control Flow

When it comes to pumping systems and how VFD’s save energy and increase production, they’re a secret weapon for increasing performance and efficiency. Rather than running your pumps at full speed continuously, regardless of demand, VFDs allow you to vary the motor speed based on the required flow rate. This means you can precisely match your pump’s output to your requirements, saving energy and increasing the life of your equipment.

VFDs in HVAC Control Atmosphere

We know that heating, ventilation, and air conditioning (HVAC) use a lot of energy. With VFDs, you have the ability to improve energy efficiency while maintaining comfort. VFDs help your HVAC system efficiency by altering fan and compressor speeds in response to real-time demand, saving you money on energy costs while maintaining a facility’s inside temperatures.

VFDs Smooth Conveyor Motion

Imagine a conveyor systems working effortlessly, with little disruption and maximum efficiency. VFDs control motor speed and torque, allowing for smooth acceleration and deceleration, decreasing strain on mechanical components and lowering the danger of jams or breakdown. Whether you’re moving things in a warehouse or managing materials on a production line, VFDs help maximize throughput while reducing energy use.

VFDs change motor speed on the fly, adapting to production and your environment.

Industries and VFD Applications Benefitting from Production, Energy Savings

| Industry | VFD Application | Production Output and Energy Savings |

| Manufacturing | Conveyor Systems | Reduced wear and tear on equipment, potentially extending equipment lifespan by up to 30%, resulting in fewer maintenance downtimes and increased production efficiency. |

| Water Treatment | Pumping Systems | Precise control of flow rates with VFDs can lead to energy savings of up to 50%, translating to significant cost reductions in operational expenses while maintaining consistent water supply. |

| HVAC | Air Handling Units | Implementing VFDs in HVAC systems can result in energy savings of 20-50%, lowering utility costs and improving comfort levels by maintaining consistent temperature and airflow. |

| Oil & Gas | Centrifugal Compressors | VFDs optimize compressor operation, reducing energy consumption by up to 40%, resulting in lower operational costs and increased profitability in oil and gas production. |

| Agriculture | Irrigation Systems | Precision control of water flow with VFDs can lead to water savings of 20-50%, improving crop yield while minimizing water usage and associated costs. |

| Mining | Crushers | Controlled motor speed with VFDs can increase crushing efficiency by up to 20%, resulting in higher throughput, reduced energy consumption, and improved profitability in mining operations. |

| Food Processing | Mixers and Agitators | VFDs enable precise control of mixing speeds, leading to up to 15% reduction in processing time, improved product quality, and increased production output in food processing facilities. |

| Packaging | Conveyor Belts | Variable speed operation with VFDs can reduce packaging line downtime by up to 25%, improving throughput, minimizing product waste, and enhancing overall packaging efficiency. |

| Textile | Spinning Machines | Adjusting motor speed with VFDs can result in up to 10% increase in yarn production, reducing production costs per unit and enhancing competitiveness in the textile industry. |

| Automotive | Assembly Line Robots | Smooth operation and adjustable speed with VFDs can improve assembly line efficiency by up to 20%, reducing cycle times, increasing production output, and enhancing overall manufacturing productivity. |