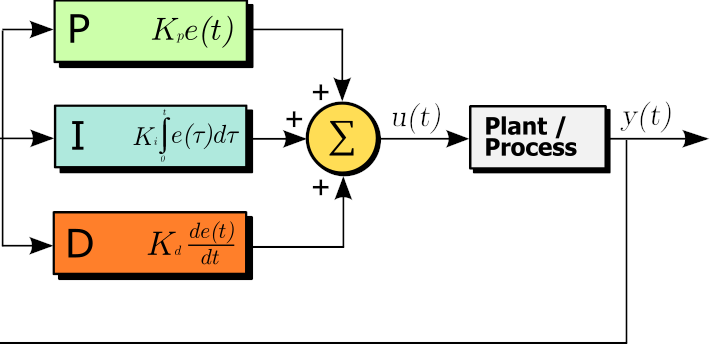

Proportional-Integral-Derivative (PID) Control automates industrial processes by adjusting system inputs to keep outputs at desired levels.

Need PID Control Products in Automation?

Get QuoteSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsPID control is important for industrial machines to work precisely, efficiently, and reliably. In this post, you will learn about how PID controllers are used in three key areas: conveyor belt systems, CNC machines, and industrial robots. These real-world examples will show you how PID controllers help improve process control and operational performance in industrial equipment like variable frequency drives, servo motors, and motor control centers.

9 PID Industrial Control Application Examples

- Regulating speed

- Controlling motors precisely

- Keeping systems stable

- Managing motor speed and torque in conveyor belt systems

- Ensuring accurate part manufacturing in CNC machines

- Enabling smooth and accurate movements in industrial robots

- Adapting to changing environments and varying weights for robots

- Optimizing performance through PID tuning in industrial processes

- Reducing errors in industrial automation

PID Controllers for Conveyor Systems

Conveyor belt systems are crucial in manufacturing and material handling. They transport products efficiently, speeding up processes. Industrial PID allows smooth and reliable operation by regulating motor speed and torque, maintaining consistent belt movement.

This is essential for precise timing and synchronization in production lines. Used in industries like automotive, food processing, and packaging, any disruption can cause significant downtime and losses. PID control in industrial automation improves efficiency and reliability, extending conveyor belt lifespan by reducing wear and tear.

Challenges

Maintaining constant speed with varying loads is a major challenge. Load changes cause speed fluctuations, leading to inefficiencies and system damage. Synchronization with other machinery can be difficult without precise control, resulting in product damage, reduced productivity, and higher maintenance costs.

Minimizing belt slippage and ensuring accurate item positioning are also challenges. Slippage due to load, friction, or tension changes can cause misalignment and production delays. PID tuning for industrial processes is essential for maintaining desired speed and position, ensuring smooth operation.

Solutions

To maintain consistent speed, PID controllers regulate motor speed and torque. They continuously monitor and adjust motor output, keeping the conveyor running smoothly despite load variations.

Industrial PID control makes possible efficient and reliable operation, reducing disruptions and downtime. Minimizing slippage and ensuring accurate positioning are achieved through precise PID tuning for industrial processes.

Simply put, a PID controller helps machines stay on track by adjusting based on how far they are from the desired position, how long they have been out of position, and how quickly they are moving away.

Summary: Conveyor Systems PID Control Applications and Solutions

| Application | Challenges | Solutions |

| Conveyor Belt Systems | Constant speed with varying loads. Minimizing belt slippage and ensuring accurate positioning | Using PID controllers to regulate motor speed and torque. Precise PID tuning for consistent operation and synchronization |

PID for industrial control is like driving a car. Steering and adjusting course and speed to stay in the lane.

– Anonymous

PID Controllers for CNC Machines

CNC (Computer Numerical Control) machines are vital in modern manufacturing, supporting precise tools like lathes, mills, and routers.

CNC PID controllers maintain precise motor movements and tool positioning, ensuring high precision. Integration of industrial PID control allows CNC machines to operate with accuracy crucial in aerospace, automotive, and electronics. This reduces waste and boosts efficiency.

Challenges

Primary challenges in CNC machines include achieving high precision and repeatability. Deviations in tool path or positioning can lead to defects, wasting materials. Controlling multiple axes simultaneously adds complexity, requiring perfect synchronization for accurate parts.

Minimizing tool wear and vibration is crucial, as they affect machine performance and product quality. Vibration causes inaccuracies, leading to errors. Addressing these challenges requires sophisticated control systems and PID tuning for industrial processes.

Solutions

CNC PID Devices regulate machine motor and tool movement to achieve high precision. PID controllers monitor tool position, adjusting motor outputs for accurate paths. This eliminates deviations so they match exact specifications, reducing waste.

Summary: CNC PID Control Applications and Solutions

| Application | Challenges | Solutions |

| CNC Machines | High precision and repeatability. Minimizing tool wear and vibration | Utilizing PID control for accurate motor movements. Advanced PID tuning to reduce vibration and extend tool life |

PID Controllers for Industrial Robots

Industrial robots are increasingly vital in manufacturing, performing tasks like assembly, welding, and packaging. Precise and complex movements are essential for their effectiveness.

Industrial automation with PID controllers offers smooth and accurate operation by regulating motor-driven joints. PID controllers guarantee precise movements and positioning, crucial for maintaining quality in manufacturing.

Challenges

Ensuring smooth and accurate movements is a major challenge for industrial robots. Precise arm and tool movements are necessary for correct task execution, with any deviation risking errors and reduced product quality.

Dynamic environments add complexity, requiring quick control system adaptation. Handling varying payloads is another challenge, with weight changes affecting balance and movement. Robust industrial automation with PID controllers is needed to deliver reliable and efficient robot operation.

Solutions

Industrial robots use PID controllers to regulate motor-driven joints, ensuring smooth and accurate movements. PID controllers continuously monitor joint position and speed, adjusting motor outputs to maintain desired paths and speeds. This precise control eliminates deviations, ensuring accurate and consistent task performance.

Summary: Industrial Robot PID Control Applications and Solutions

| Application | Challenges | Solutions |

| Industrial Robots | Smooth and accurate movements. Handling varying payloads. | Implementing PID control for precise joint regulation. Fine-tuning PID parameters to adapt to load changes |

PID Control for Manufacturing Efficiency and Reliability

PID control is a key component in industrial automation, delivering precision and efficiency across a wide range of applications.

In conveyor belt systems, industrial PID control promises steady speed while minimizing slippage, increasing production, and lowering downtime. CNC PID control gives tremendous accuracy and repeatability for CNC machines, which are required for the production of accurate and high-quality components. PID control enables industrial robots to move smoothly and accurately while adapting to changing environments and payloads.

By applying PID control to industrial automation, manufacturers can reach peak efficiency, increase reliability, and eliminate production mistakes, making it a key part of modern manufacturing processes.