NEMA motor starter ratings for electrical parts are established for managing starting and stopping electric motors. These starters meet the National Electrical Manufacturers Association’s (NEMA) standards for Industrial Automation performance.

In this post, you’ll learn why International Electrotechnical Commission (IEC) and NEMA motor starters follow separate worldwide standards, affecting their design and operation.

Need NEMA / IEC Starters?

Get A Quote HereSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsTable of contents

- Comparing NEMA and IEC Starter Design

- NEMA Motor Starter Advantages and Disadvantages

- NEMA Compared to Solid-State Motor Starters

- Upfront Cost of NEMA Starters

- Environmental Impact of Replacement Part Electronic Waste

- Motor Starter Maintenance and Reliability

- Future Trends in Motor Starters

- NEMA Motor Starter Ratings and Applications

- Test Your Knowledge

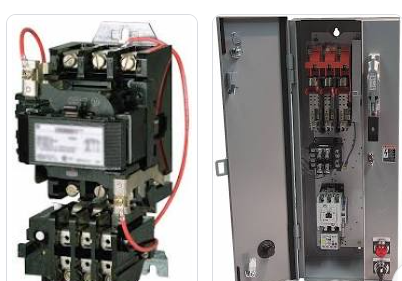

Comparing NEMA and IEC Starter Design

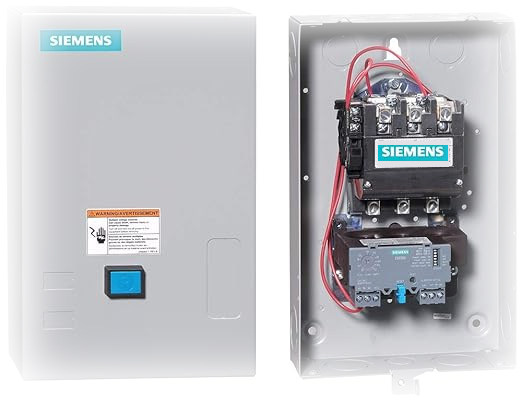

Comparing NEMA and IEC motor starters, several differences show, especially in their design, construction, and geographical applications. NEMA starters with NEMA motor starter ratings are widely used in North America, IEC starters dominate the global market. IEC starters have a standardized design and more compatibility. NEMA standards are good for durability and environmental protection, while IEC standards emphasis modularity and interchangeability.

NEMA Motor Starter Advantages and Disadvantages

Starters with NEMA ratings have several advantages, including their strong structure, interoperability with existing systems, and a wide range of replacement components. However, they may have limits as compared to other varieties, such as a larger size and greater expenses connected with certain ratings. Despite these disadvantages, NEMA starters remain popular in areas where durability and dependability are critical.

NEMA Compared to Solid-State Motor Starters

Comparing NEMA motor starters with solid-state starters reveals differences in efficiency, precision, and application suitability. Solid-state starters offer higher efficiency and precise motor control but may come with higher initial costs. NEMA starters, on the other hand, are well-suited for rugged environments and applications where reliability is crucial, such as heavy machinery and industrial equipment.

Upfront Cost of NEMA Starters

When calculating the cost and size of NEMA motor starters, issues such as upfront investment, installation costs, and long-term maintenance are important. While NEMA starters have greater upfront prices and bigger physical footprints than alternatives such as solid-state starters, their longevity and dependability frequently result in cost benefits during the equipment’s lifetime. The size and space requirements of NEMA starters must be carefully considered to guarantee compatibility with current infrastructure.

Environmental Impact of Replacement Part Electronic Waste

The environmental benefits of using NEMA motor starter ratings over alternative solutions are considerable, including energy efficiency, sustainability, and material utilization. While NEMA starters may not always provide the same degree of energy efficiency as solid-state starters, their strong construction and longevity promote sustainability by eliminating the need for frequent replacements and electrical waste. Real-world examples and case studies illustrate NEMA motor starters’ practical applicability in a range of industries, as well as instances in which other types of starters may be preferred. For example, NEMA starters are widely used in heavy industrial environments like manufacturing facilities and mining operations, where dependability and longevity are important. Solid-state starters, on the other hand, may be chosen in conditions requiring precise motor control and energy economy. A discussion of NEMA ratings is found in many cases studies where electronic waste is a featured topic.

Motor Starter Maintenance and Reliability

Comparing NEMA starters’ maintenance needs and dependability against alternatives, trade-offs between durability and complexity are clear. While NEMA starters are known for their rugged design and low maintenance requirements, solid-state starters provide advantages like as decreased wear and tear and extended operating lifespans. Environmental variables, operating temperatures, and application requirements all play a role in the specific maintenance and lifespans.

Future Trends in Motor Starters

Comparing NEMA starters’ maintenance needs and dependability against alternatives, trade-offs between durability and complexity are clear. While NEMA starters are recognized for their tough design and low maintenance requirements, solid-state starters provide advantages such as decreased wear and tear and extended operating lifespans. Environmental variables, operating temperatures, and application requirements all play a role in the specific maintenance and lifespan concerns for each kind.

NEMA Motor Starter Ratings and Applications

| NEMA Rating | Application | Example Application |

| NEMA 1 | Constructed for indoor use and provides protection against human contact with live electrical parts. Protects equipment from falling debris (dirt). | Indoor electrical panels or cabinets |

| NEMA 2 | Essentially the same as NEMA 1 but offers additional protection, including protection from light dripping or splashing of water (drip-proof). | Indoor electrical panels in areas where light dripping or splashing may occur |

| NEMA 3R, 3RX | Engineered for indoor or outdoor use. Protects against rain, sleet, snow, and dirt. Prevents ice formation on the enclosure. | Outdoor electrical installations exposed to the elements |

| NEMA 3, 3X | Rain-tight, sleet-tight, and dust-tight for indoor and outdoor use. Added protection against dust compared to NEMA 3R or 3RX. | Outdoor electrical enclosures requiring dust-tight protection |

| NEMA 3S, 3SX | Offers the same protection as NEMA 3 but remains operable when covered in ice. | Outdoor electrical enclosures in cold climates |

| NEMA 4, 4X | Intended for indoor or outdoor use. Provides protections against water ingress and/or hose-directed water in addition to NEMA 3 protection. | Outdoor electrical enclosures in wet environments |

| NEMA 6, 6P | Same as NEMA 4, with additional protection from temporary or prolonged water submersion up to a designated depth (6P). | Outdoor electrical enclosures in areas prone to flooding |

| NEMA 7 | Explosion-proof and designed for indoor use in hazardous locations. | Facilities with explosive gases or vapors |

| NEMA 8 | Offers the same protection as NEMA 7 but can be used both indoors and outdoors in hazardous locations. | Hazardous locations with varying environmental conditions |

| NEMA 9 | Dust-ignition-proof and intended for indoor use in hazardous locations. | Facilities with combustible dust in the air |

| NEMA 10 | Meets MSHA (Mine Safety and Health Administration) standards. | Mining equipment and installations |

| NEMA 12, 12K | Intended for general-purpose indoor use. Protects against dripping and splashing water, rust-resistant, and without knockouts. | Indoor electrical panels in non-hazardous environments |

| NEMA 13 | General-purpose indoor use. Same protection as NEMA 12 with added protection against dripping and/or sprayed oils and coolants. | Indoor electrical panels in environments with oil or coolant exposure |

Test Your Knowledge

(Click Question to See Answer)

NOTE: This post is for educational purposes only. Electrical systems can be hazardous, and working with them without the necessary expertise and training can be dangerous. We recommend getting the assistance of a certified electrical professional if you’re not already a qualified electrician. Performing electrical work without the needed knowledge and training may lead to severe injuries, electric shocks, or damage to the equipment. Always prioritize safety and, when in doubt, contact a qualified electrician.