These Electric Motor Starter questions and answers explore common situations maintenance technicians encounter when repairing, replacing, and testing electric motors and starters to solve issues with an electric motor that won’t start or that stalls.

Learn to detect problems and keep your electric motor operating as designed by troubleshooting and fixing faulty and malfunctioning motor starters. We’ll cover the methods to troubleshoot a faulty electric motor starter and get the best possible performance from your motor control systems.

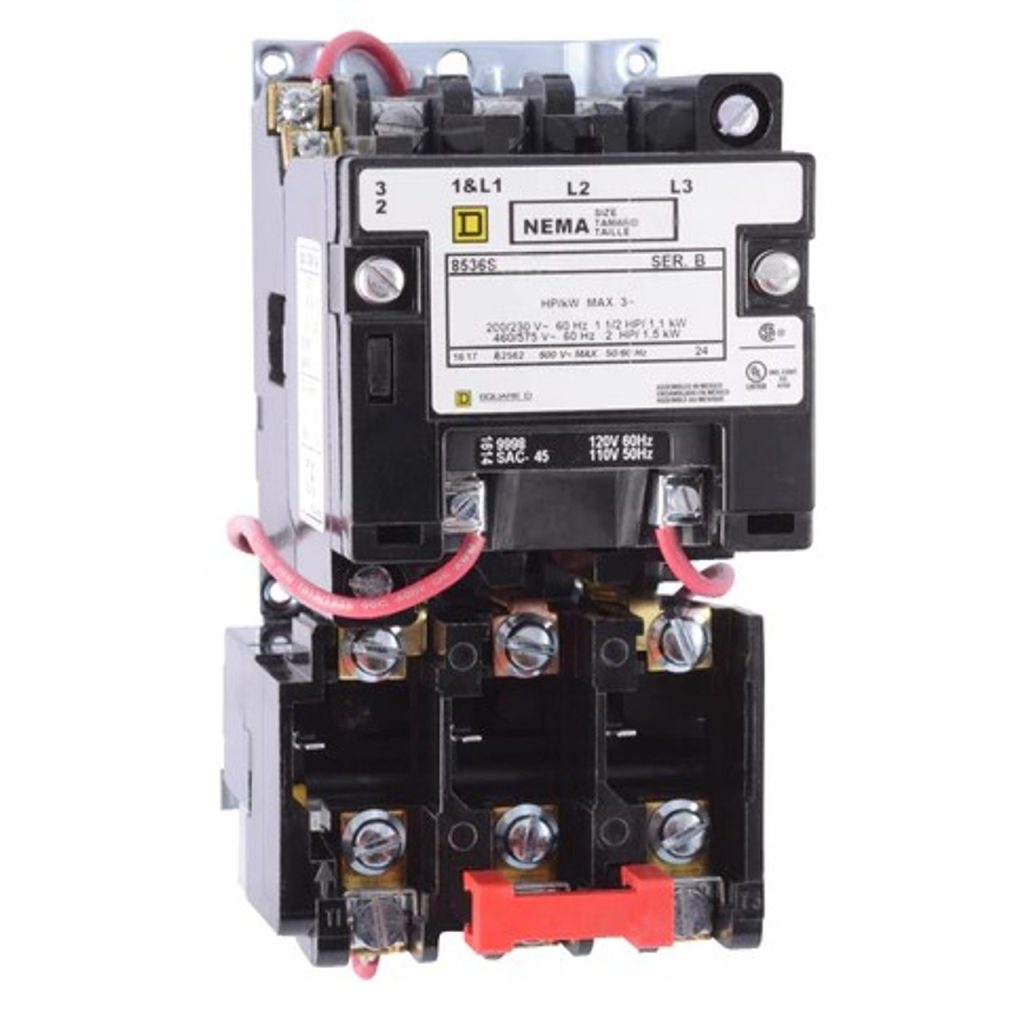

Need Electrical Motor Starters?

Get A QuoteSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsQ: What are the signs of a faulty electric motor starter?

A: During startup, grinding, clicking, or buzzing noises might indicate a problem with the motor starter. Grinding indicates mechanical wear, clicking indicates solenoid issues, and buzzing might indicate a malfunctioning relay or damaged components.

Q: How can I know if the electric motor starter has a severe problem?

A: A burning odor or smoke around the engine is a definite sign of trouble. These symptoms, caused by overheating within the motor starter, require immediate attention. Ignoring such warnings may cause more damage and safety issues, so fast action is necessary.

Q: What is the function of overload protection in electric motor systems, and how does it relate to the starter?

A: Continuous overloading can result in overheating, increased component deterioration, and, in severe cases, motor failure. Recognizing the effects of repeated overload trips is crucial for taking the right action and preventing additional damage to the motor system.

Q: Can faulty electric motor starters affect motor speed and performance?

A: Yes, issues with the electric motor starter, such as worn-out contacts, broken wiring, or malfunctioning solenoids, can directly impact motor speed and performance. Recognizing and addressing these issues promptly will help extend the life of your electric motor starter.

Q: What are the signs of motor speed or performance inconsistency?

A: Electric motor speed or performance inconsistency may appear as abrupt changes or erratic operation. Regular monitoring and quick detection of these signals are essential. They allow personnel to troubleshoot an electric motor starter, make timely repairs, and maintain the dependability of the motor system.

Q: How can I troubleshoot and fix problems with the electric motor starter?

A: Troubleshooting involves interpreting unusual noises, identifying burning odors or smoke, understanding motor overload protection, and recognizing signs of inconsistent motor speeds.

Once an issue is identified, repairs, such as replacing worn-out parts or addressing wiring problems, can be performed to help the electric motor starter operate smoothly.

Inspecting, Troubleshooting, and Testing Electric Motor Starters

Q: How can visual examination help identify problems with the electric motor starter?

A: A visual examination is needed to spot issues, such as wear, corrosion, or loose connections in the motor starter. By inspecting components like the solenoid, contacts, and wiring, technicians can visually evaluate the starter and gather information about its condition.

Q: What standard test methods should be used to diagnose faulty electric motor starters?

A: Basic diagnostic tests, such as continuity checks and voltage readings, give valuable information about the health of the electric motor starter. By combining visual inspection and testing, maintenance personnel fully understand the starter’s condition, which helps you troubleshoot an electric motor starter.

Q: What’s the purpose of a motor starter troubleshooting checklist in getting my electric motor started?

A: Your motor starter troubleshooting checklist is a handy tool that outlines common causes of motor starter problems, such as worn-out contacts, damaged wiring, or malfunctioning relays. This checklist identifies potential issues and provides solutions and repairs, helping technicians restore the motor starter to its full potential.

Q: How can I ensure the motor starter receives the proper voltage and power supply?

A: Check the power supply to the motor starter, making sure there are no interruptions or fluctuations. Seeing the correct voltage is crucial for the proper functioning of the motor starter.

Q: What should I do if the motor starter is not working, and how can circuit breakers and fuses help?

A: Inspect the circuit breakers and fuses connected to the motor starter. Look for tripped breakers or blown fuses and replace them as needed. This can often resolve issues related to power interruptions or overloads.

Q: Why is inspecting wire connections important when troubleshooting a faulty motor starter?

A: Inspecting wiring connections, especially those between the motor starter and the motor, ensures they are secure and free of damage or corrosion. Faulty connections can disrupt the electrical flow and affect the motor starter’s performance.

Electric Motor Stopped and Isn’t Starting

Q: Why did my motor stop, and how can I fix it if the overload tripped?

A: If your motor has stopped and the overload has tripped, it’s a common occurrence designed to protect it from excessive current. Simply press the red button on the overload to reset it, similar to resetting a circuit breaker. Also, verify that the reset is in “manual” mode by checking the position of the red button.

Q: What should I do if resetting the overload doesn’t work, and how do I check if the overload has failed?

A: If resetting the overload doesn’t resolve the issue, you can perform a quick check to see if the overload has failed. Disconnect power, lockout/tag out if necessary, and use an ohmmeter to check continuity between the two Normally Closed (NC) terminals on the overload. If the ohmmeter shows “OPEN,” the overload is faulty and needs replacement.

Q: What should I do if I’m missing one or more phases in my motor circuit?

A: If you’re missing one or more phases and fuses are part of the circuit, disconnect the power and use a multimeter to check continuity across the fuses. Replace any blown fuses. Check for corrosion in the fuse holders, and if present, clean it with an electrical contact cleaner and an old toothbrush.

Q: How can I fix a blown fuse in my motor circuit, and what should I check for if one is blown?

A: If you encounter a blown fuse, replace it. Check fuse holders for corrosion, as this can disrupt continuity. Clean any corrosion with an electrical contact cleaner and an old toothbrush. This simple maintenance step can resolve issues related to blown fuses and ensure the smooth operation of your motor.

You should now have the basic knowledge to troubleshoot faulty electric motor starters. You can help your electric motor run its best by quickly diagnosing and testing methods to repair and replace broken parts. Use these troubleshooting techniques and maintenance procedures to keep your motor control systems operating at maximum efficiency.

With this information, you can better analyze and solve starter-related motor issues in your electrical system. At Relectric, we supply motor starters and other electrical parts to help you with your projects. We’re here to help! 800.497.6255

IMPORTANT: Electrical systems can be hazardous, and working with them without the necessary expertise and training can be dangerous. If you’re not a qualified electrician or don’t have experience diagnosing a bad starter, it’s highly recommended to get the assistance of a certified electrical professional. Performing electrical work without the needed knowledge and training may lead to severe injuries, electric shocks, or damage to the equipment. Always prioritize safety and, when in doubt, contact a qualified electrician about how to replace a bad electrical starter and related electrical maintenance.