Beginning with a complete Visual Inspection, we’ll go into identifying damage in electrical contactors like burning, corrosion, or loose connections. We’ll learn how to recognize unusual noises that may indicate electrical contactor problems, and how to handle overheating concerns caused by overloads or faulty connections.

We’ll also look at the importance of Contact Resistance Measurement, which offers information on the contactor’s health. Finally, you’ll learn about Control Circuit Examination, which confirms that signals are working properly. So, let’s dissect these critical troubleshooting techniques to diagnose a bad contactor.

Need To Replace Your Contactor?

Get A Quote NowSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsRegular Maintenance and Troubleshooting for Electrical Equipment Functionality: Regular maintenance and troubleshooting of electrical contactors is needed for accurate electrical equipment functioning. Scheduled maintenance and diagnosis of problems means smooth electrical power performance. Early detection and repair of contactor faults saves serious failures, increases equipment life, and reduces downtime.

Understanding Different Types and Configurations of Contactors: Contactors are available in a variety of types and combinations, such as definite purpose, reversing, and lighting contactors. Each variety is designed for a specific use and varies in contact configurations, coil voltages, and size. Understanding these differences is critical for efficient diagnosis and replacement of electrical contacts.

Identifying Common Contactors Issues and Solutions: Contactors frequently have problems like failure to function, closing, welding, or arcing. Inspecting contacts for damage or wear, checking control circuits, and testing for continuity are all part of troubleshooting these issues. Effective solutions may be applied by recognizing these common problems.

Step-by-Step Troubleshooting Methods for Contactors: Troubleshooting to replace a bad electrical contactor requires a systematic approach. Testing for continuity, assessing contacts for corrosion or wear, and testing control circuits are all necessary procedures. Each problem needs a different troubleshooting strategy for how to test a contactor.

Using Multimeters and Testing Equipment for Electrical Contactor Problem Solving: Troubleshooting contactors requires specific tools like multimeters, insulated gloves, and screwdrivers. Multimeters and testing equipment are important for evaluating contactor problems. They help with continuity, control circuits, and contact integrity testing. A thorough understanding of these tools assures accurate diagnosis and successful solutions.

Prioritizing Safety Protocols for Contactor Troubleshooting: When troubleshooting contactors, safety comes first. Following safety rules, such as de-energizing circuits and wearing suitable protective equipment, is critical for avoiding electrical dangers during troubleshooting procedures.

What to Look for to Determine if an Electrical Contactor Is Bad

Visual Inspection: Look for visible signs of damage on the contacts, such as scorched or melted regions, pitting, corrosion, or wear. Inspect the contactor for any loose connections or damaged parts.

Irregular Noises: Listen for unusual buzzing or humming noises emanating from the contactor, which might indicate arcing or faulty contact.

Overheating: Feel the contactor to see whether it is overheating. Overheating can be caused by an overload, defective connections, or a problem with the control circuit.

Inconsistent Operation: Examine whether the contactor runs sporadically or whether the attached equipment operates inconsistently. Erratic functioning may indicate a faulty contactor.

Electrical Testing: Use a multimeter to test the contactor’s coil for continuity to see if it’s receiving the correct control signal and if you need to replace a bad electrical contactor.

Contact Resistance Measurement: Measure the resistance across the contacts when the contactor is open and closed. An abnormal resistance might indicate a bad or faulty contactor.

Control Circuit Examination: Inspect the control circuit to see that it’s sending the correct signals for the contactor to engage or disengage.

Thermal Imaging: Use a thermal imaging camera to find hot spots or unusual temperatures in the contactor, which can be a sign of potential problems.

Age and Service Life: The contactor may just be old and beyond its service life. Older contactors can fail due to wear and tear.

Electrical Maintenance Records: Go through maintenance records to see when the contactor was last repaired or changed, which will give you an idea of its possible lifetime and current condition.

This list above will help electrical maintenance personnel determine the condition of an electrical contactor and diagnose a bad contactor for repair or replacement.

Q&A on Troubleshooting and Replacing Electrical Contactors

Q: What safety precautions should I take before working on electrical contactors?

A: Make sure the power is off, follow lockout/tagout procedures, and wear appropriate personal protective equipment to prevent hazards.

Q: What should I look for during a visual inspection of an electrical contactor?

A: Look for visible signs of damage, overheating, or wear on the contacts, and check for melted plastic or metal pieces inside the contactor.

Q: How can I test the contactor for continuity?

A: Check the contactor coil for continuity using a multimeter. This test determines whether the coil is working properly.

Q: Why is it important to check the control circuit when troubleshooting a contactor?

A: The control circuit is tested to confirm that the contacts are getting the necessary signals for activation, which is required for the contactor to work.

Q: What should I look for when inspecting the contacts of a contactor?

A: Inspect the contacts for signs of pitting, arcing, or welding, which can prevent the contactor from functioning or closing the way it should.

Q: When and how should I clean or replace the contacts in a contactor?

A: Clean contacts using contact cleaner and abrasive materials to remove buildup. If damage is really bad, replacement might be the solution.

Q: What’s the final step after replacing a contactor in a system?

A: When the new contactor is in place, turn the power on and test the system to see that the contactor is functioning as it should.

Quick Reference: Contactor Types, Applications and Functions

| Type of Contactor | Common Equipment Usage | How the Contactor Works |

| Definite Purpose Contactors | Motors, Compressors | Definite purpose contactors control specific functions in electrical systems, enabling or disabling power to a particular device or system, like a motor or compressor. |

| Reversing Contactors | Elevators, Conveyors | Reversing contactors support reversing the direction of rotation in motors, allowing for bi-directional movement in places like elevators or conveyor belts. |

| Lighting Contactors | Streetlights, Stadium Lights | Lighting contactors manage large lighting systems, so the switching on/off and controlling stadium lights or street lighting is working. |

| HVAC Contactors | Air Conditioning, Heating | HVAC contactors control power supply to heating or cooling systems, managing air conditioning and heating units in residential and commercial places. |

| Latching Contactors | Power Supplies, Lighting Control | Latching contactors are either open or closed, even when the control signal is removed, usually used in power supply systems and lighting control. |

| Miniature Contactors | Appliances, HVAC Systems | Miniature contactors are found in smaller systems like household appliances or smaller HVAC systems, controlling power throughout the house or building. |

| Reversing Magnetic Contactors | Industrial Motors, Elevators | Reversing magnetic contactors operate like reversing contactors but use magnetic fields to control the direction of motors or systems like elevators. |

7 Heavy Industrial Equipment Applications Where Electrical Contactors are Used

- Industrial Motors: Contactors regulate big industrial motors found in machinery, conveyors, pumps, and other equipment. They help with starting, stopping, and reversing the motor’s activity.

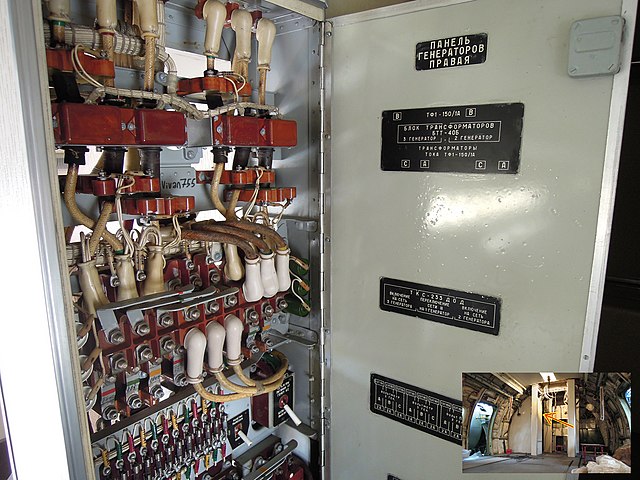

- Generators: Contactors are used in heavy-duty generators to manage energy flow, start and stop power generation, and control power distribution.

- Transformers: Contactors help control the electrical current flow, protecting against overloads and short circuits.

4. Industrial HVAC Systems: Large heating, ventilation, and air conditioning systems to control motors, compressors, and other electrical components.

5. Heavy-duty Compressors: Contactors play an important role in heavy-duty compressors, controlling the electric power supply.

6. Large Pumps: Contactors support the control and operation of pumps in heavy industries like wastewater treatment plants mining operations.

7. Industrial Lighting Systems: For large-scale lighting systems in industrial settings, contactors control power supply, allowing lights to be switched on/off and managing building lighting operations.

Understanding the relevance of regular maintenance and troubleshooting to diagnose a bad contactor is critical for adequately operating electrical equipment. I hope this procedure has shown you that periodic maintenance and prompt issue detection are critical for guaranteeing consistent and efficient electrical power performance.

Early detection and correction of contactor problems prevent serious failures, increase electrical equipment life, and considerably minimize downtime. With this information, you can better analyze and solve starter-related motor issues in your electrical system. At Relectric, we supply motor starters and other electrical parts to help you with your projects. We’re here to help! 800.497.6255

IMPORTANT: Electrical systems can be hazardous, and working with them without the necessary expertise and training can be dangerous. If you’re not a qualified electrician or don’t have experience diagnosing a bad contactor, it’s highly recommended to get the assistance of a certified electrical professional. Performing electrical work without the needed knowledge and training may lead to severe injuries, electric shocks, or damage to the equipment. Always prioritize safety and, when in doubt, contact a qualified electrician about how to replace a bad electrical contactor and related electrical maintenance.