Investing in energy-efficient electric motors helps to significantly reduce your facility’s carbon impact during production processes.

Need Variable Frequency Drive Automation Products?

Get VFD QuoteSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsSaving Energy with Electric Motors in Industrial Controls

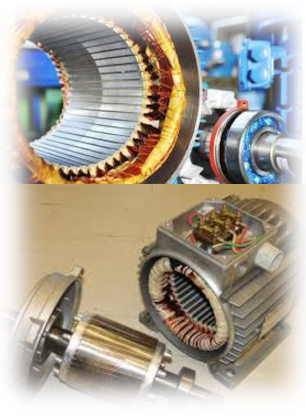

Energy-efficient electric motors are meant to transform electrical energy into mechanical energy while minimizing losses. “Going green” with efficient electric motors improves efficiency by minimizing wasted energy, making them important to industries looking to reduce energy expenses. To offer peak performance, these motors are designed with high-quality materials and modern production procedures.

Using energy-efficient electric motors in industrial applications is important for lowering operating costs and increasing sustainability. These motors not only save energy but also improve the efficiency of your production processes. Investing in high-efficiency motors helps to significantly reduce your facility’s carbon impact.

There are several types of energy-efficient motors available, which are classified according to their efficiency level. The most commonly used are IE3, IE4, and IE5 motors. For example, the WEG W22 Super Premium motor is known for high efficiency and dependability, making it a popular choice among companies looking to optimize energy use and performance.

Variable Frequency Drives’ Role in Motor Efficiency

VFDs play an important role in increasing motor efficiency. VFDs save energy by regulating the speed and torque of electric motors by altering the input frequency and voltage. This capacity enables precise control of motor operation, making sure the motor runs only at the speed required for the task, significantly lowering energy usage.

VFDs play an important part in improving motor efficiency. VFDs control the speed and torque of electric motors by adjusting the input frequency and voltage. This capability lets you have precise control of motor operation, so the motor only runs at the speed required for the task, resulting in significant energy savings.

In addition to VFDs, servo drives and soft starters help to improve energy efficiency. Servo drives offer accurate motion control, which is useful in applications needing great accuracy. Soft starts, on the other hand, gradually increase the motor’s voltage, lowering inrush currents and mechanical stress and increasing motor life and efficiency.

Benefits of Energy-Efficient Motors and Drives

Investing in energy-efficient motors and drives saves the company’s money over time. The initial expenditure is frequently offset by savings on energy costs, lower maintenance costs, and longer equipment life. This financial benefit makes energy-efficient technology a wise investment for any forward-thinking company.

By using energy-efficient electric motor drives and other sustainable industrial automation solutions, you may drastically lower your carbon footprint and greenhouse gas emissions. This not only helps you comply with environmental standards, but it also boosts your company’s reputation as a responsible and eco-friendly organization. Energy-efficient motors and drives boost the performance and dependability of your industrial equipment.

High-efficiency electric motors run cooler and with less vibration, which means less wear and tear. This increased reliability lowers the frequency and expense of maintenance, resulting in reduced downtime and more constant manufacturing output.

Examples of Motor Control Energy-Saving Products

| Product Category | Description and Examples |

| High-Efficiency Motors | IE3, IE4, and IE5 motors: These motors offer higher efficiency levels. Example: WEG W22 Super Premium Efficiency motor (WEG) (ARCweb). |

| Variable Frequency Drives (VFDs) | Optimize motor performance by controlling speed and torque. Example: ABB’s VFDs enhance motor efficiency and reduce energy use (ABB Group) (Plant Engineering). |

| Servo Drives | Provide precise motion control, essential for high accuracy and efficiency, reducing energy waste and improving performance. |

| Soft Starters | Gradually increase motor voltage, reducing inrush currents and mechanical stress, enhancing motor lifespan and efficiency. |

| High-Efficiency Pumps | Designed to reduce electricity use in water supply and HVAC systems. Example: Energy-efficient centrifugal and submersible pumps. |

| Advanced Lighting Systems | LED lighting and smart lighting control systems reduce energy consumption significantly compared to traditional solutions. Example: Integrated lighting controls. |

| Building Automation Systems (BAS) | Integrate HVAC, lighting, and other systems to optimize energy use across the facility using sensors and control algorithms. |

| Heat Recovery Systems | Capture and reuse waste heat from industrial processes, leading to substantial energy savings. Example: Heat exchangers and recovery ventilators. |

| Insulated Bearings and Shaft Grounding Systems | Reduce energy losses in motors by preventing electrical discharge through bearings, extending motor life and improving efficiency |

| Energy-Efficient HVAC Systems | High-efficiency chillers, boilers, and air handling units reduce energy for heating and cooling. Variable speed drives on HVAC equipment further optimize performance. |

Choosing Motors, Drives to Replace Industrial Equipment

Choosing the correct replacement electric motors and drives is necessary for reaching peak energy efficiency. When selecting energy-efficient motors, consider the motor’s efficiency rating, compatibility with current systems, and your application’s specific operational needs. It is important to speak with experts and use simulation tools to make informed decisions.

To successfully integrate new technologies into existing processes, recommended practices include doing a complete review of your current setup, training your team on the new technology, and developing a solid monitoring and maintenance strategy. This makes sure that your energy-efficient solutions provide the greatest benefits and continue to work consistently over time.

Focusing on energy-efficient motor drives and other modern motor control automation systems for energy savings is going to enhance your industrial motor performance optimization efforts. This strategic approach not only lowers energy usage, but also improves the entire efficiency and sustainability of your industrial operations.