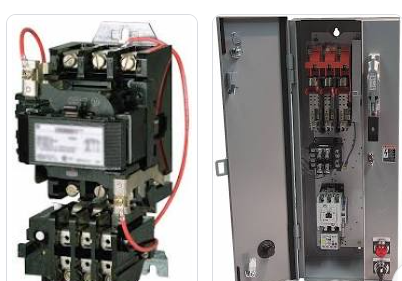

Choosing and installing NEMA motor starters requires specific knowledge. This post reviews the complexities of selecting a NEMA motor starter, including installation tips and best practices for motor and electrical system compatibility.

We’ll walk you through the process of selecting the correct NEMA starter, looking into important considerations, and providing professional insights for a smooth install. The motor starter sizing tips help you make informed selections that are specific to your application.

We also provide best practices for greater compatibility, helping you to improve the performance and lifetime of your electrical systems. From the fundamentals of NEMA motor starting selection to advanced installation procedures, this guide is a road map to motor maintenance and selecting a NEMA motor starter.

Need NEMA Motor Starters?

Get QuoteSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsNEMA Starter Selection: 7 Best Practice Tips

Determine Motor Size and Type: The proper NEMA starting size improves compatibility with the motor’s power needs. Overheating and power loss are avoided with proper size, which improves overall system performance.

Consider Environmental Conditions: Choosing the right NEMA enclosure type (e.g., NEMA 1 for general purpose or NEMA 4 for wet environments) guards the starter and motor from environmental factors, extending equipment life and reliability.

Evaluate Application Requirements: Understanding the application’s individual requirements allows for selecting features such as thermal overload protection or extra control choices, boosting the NEMA starter’s ability to meet the system’s unique requirements.

What You Need to Know About Motor Starter Installation

Once you’ve selected a starter, you’re ready for installation. Reading the motor starter installation manual outlines safety precautions and guidelines specific to the electric motor starter. Below are key considerations you will find in the installation manual and why they’re important for properly installing your starter.

See your user’s manual for these important topics before installing the starter.

| Installation Manual Topic | What You Need to Know |

| Mounting Considerations | Guidelines on selecting an appropriate location for mounting the NEMA starter, considering factors like accessibility, ventilation, and proximity to the motor. |

| Wiring and Termination Techniques | Best practices for correctly wiring the NEMA starter, including proper termination techniques, cable management, and ensuring compliance with electrical codes. |

| Grounding Procedures | Detailed instructions on proper grounding procedures to enhance safety, mitigate electrical hazards, and comply with regulatory requirements. |

| Interlocking and Control Integration | Insights into interlocking mechanisms and methods for seamlessly integrating the NEMA starter with control systems, ensuring synchronized operation and preventing malfunctions. |

| Testing and Commissioning Protocols | Step-by-step procedures for testing the NEMA starter after installation, including commissioning protocols to verify its functionality and troubleshoot any issues. |

| Documentation and Record-Keeping | Guidance on maintaining comprehensive documentation, including wiring diagrams, operational parameters, and record-keeping practices for future reference and troubleshooting. |

| Safety Precautions During Installation | A comprehensive overview of safety precautions to be observed during the installation process, including personal protective equipment (PPE) requirements and safe work practices. |

| Environmental Considerations | Tips on safeguarding the NEMA starter against environmental factors during installation, such as protection against dust, moisture, and extreme temperatures. |

| Emergency Shutdown Procedures | Instructions for implementing emergency shutdown procedures and installing features like emergency stop buttons, enhancing the safety and quick response capabilities of the system. |

| Routine Inspection and Maintenance | Recommendations for routine inspections and maintenance tasks to be performed after installation, ensuring ongoing reliability and identifying potential issues before they escalate. |

NEMA Starter Vs. IEC Motor Starter Pros and Cons

NEMA starter technology is governed by National Electrical Manufacturers Association standards. This means standardized sizing and wiring configurations for different applications. This can simplify selection and installation. Alternative starters like IEC or electronic soft starters may provide global conformity, advanced motor protection, and smoother starts with different sizing conventions and technology.

NEMA Starter Pros

Standardization: NEMA starters adhere to standardized sizing and wiring configurations, supporting easy selection and installation.

Enclosure Options: Various enclosure types (NEMA 1, 3R, 4, etc.) provide flexibility for different environmental conditions.

Application Range: Suited for many applications, from small motors to large industrial setups.

Widespread Adoption: Commonly used in North America, helping with availability of components and familiarity among motor control technicians.

NEMA Starter Cons

Regional Focus: Primarily adopted in North America, which can limit compatibility with global systems.

Limited Technology: May lack some of the advanced features offered by other starters, like electronic soft starters.

Selecting a NEMA motor starter can seem complicated. This post is a companion for unpacking the challenge. Whether you’re choosing the right NEMA starter or seeking motor starter sizing guidance, we’ve walked you through considerations and provided professional tips for a seamless NEMA motor starter installation. The best practices support optimal motor starter compatibility with your motor control system. The end result will be improved electrical system performance and longevity.

Looking for a reputable and reliable supply partner for low and medium voltage electrical products? Speak with a friendly product specialist about your project needs at 800.497.6255.

IMPORTANT: Electrical systems can be hazardous, and working with them without the necessary expertise and training can be dangerous. If you’re not a qualified electrician or don’t have experience selecting motor starters, it’s highly recommended to get the assistance of a certified electrical professional. Performing electrical work without the needed knowledge and training may lead to severe injuries, electric shocks, or damage to the equipment. Always prioritize safety and, when in doubt, contact a qualified electrician about how to select and install an electrical starter and perform related electrical maintenance.