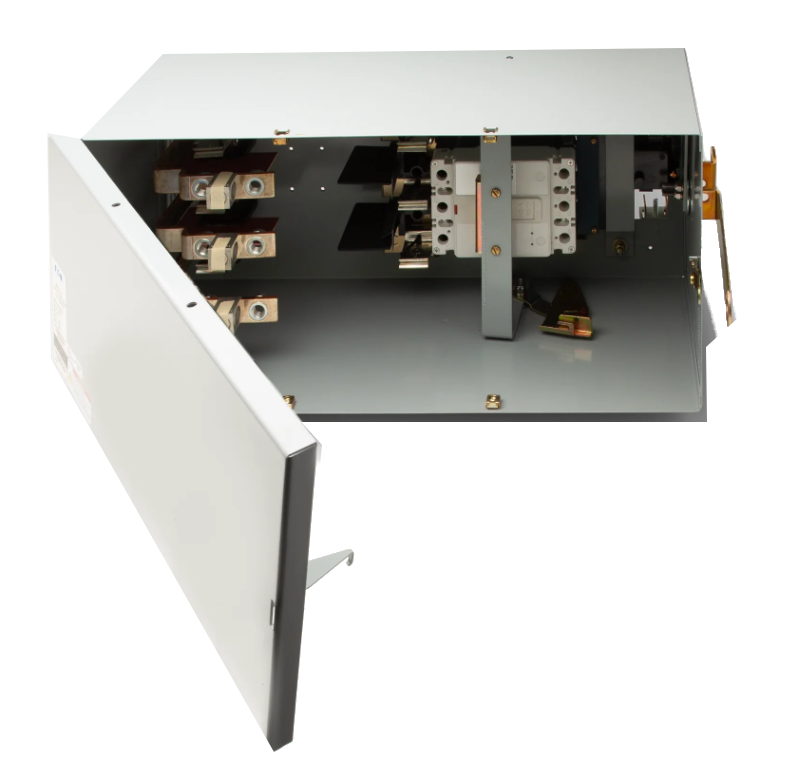

ITAP bus plugs are designed especially for the Pow-R-Way I and II busway structures.

Need ITAP Bus Plugs?

Get Bus Plug QuoteSell To Us

Got Electrical Equipment You Don't Need?

Reduce Your Electrical Inventories & Earn Cash

Sell My EquipmentPanelboard

Need a Panelboard for Your Project/Job?

Our Experienced Sales Engineers Can Help Design the Right Panelboard For You

Learn MoreTransformer Oil Testing

Is Your Transformer Due For Servicing?

Get Your Oil Analysis & Fluid Testing Done By Our NETA-Certified Techs

Learn MoreElectrical Product Resources

Product Training Product Safety Product Guides Product News Featured ProductsITAP bus plugs are specifically made for Eaton Pow-R-Way I and II Busway systems (marketed under Eaton/Cutler Hammer Busway), perfect for high-amperage setups. The staggered or offset stab arrangement differentiates them from TAP plugs, providing better contact and reliability for larger Eaton ITAP busway electrical loads.

You’ll commonly use ITAP plugs in 200 amp Pow-R-Way busway systems or even 2000 amp Pow-R-Way busway systems, handling up to 600 volts. These plugs are made for use with busway circuit breakers, busway fusible plugs and switches, and other heavy-duty busway systems, as seen in the Eaton busway catalog.

Example ITAP Part Numbers from Eaton Busway Catalog:

ITAP200N – Eaton Busway – Manufacturer Part Name: ITAP200N; POW-R-WAY1 Neutral Assembly

ITAP321GN – Eaton Busway – Manufacturer Part Name: ITAP321GN; PRW 30 AMP 120/208V FUSIBLE PLUG W/ INT GRD & 100 NEUT

ITAP322 – Eaton Busway – Manufacturer Part Name: ITAP322; 60A 240V FUSIBLE PLUG-IN BUS PLUG

How to Identify ITAP Plugs Vs. TAP Bus Plugs

The stab configuration and catalog numbers make it easy to recognize ITAP plugs for Eaton ITAP busway. These numbers identify the voltage and amperage rating of the individual plug, as well as its stab arrangement. Even though ITAP and TAP plugs appear identical from the outside, their stab configurations aren’t interchangeable.

ITAP plugs are made to handle substantially higher loads (up to 4000A), so they’re good for bigger, more demanding electrical installations. TAP bus plugs, on the other hand, include a basic aligned stab arrangement and are used in systems with current ratings of up to 1000A.

This comparison demonstrates how identifying the right plug type can be vital for keeping system compatibility and providing safety in power distribution systems.

Eaton Pow-R-Way Busway Design, Engineering

Eaton ITAP busway systems provide safety by following NEMA standards and have a range of designs for feeder and plug-in systems while following strict safety regulations.

The Pow-R-Way II system rated for 225-400 amps has copper or aluminum bus bars. This system is great for interior plug-in or feeder applications, including bolt-free connections for quick construction and excellent performance in a 600-volt system.

Pow-R-Way Design (600-5000 Amps) Components, Fittings

Pow-R-Way busway systems, rated for up to 5,000 amps, provide flexibility in both feeder and plug-in applications. These busways containing copper or aluminum bus bars can be used both indoors and outdoors. The structure supports interchangeable fittings and adaptor-free installation.

You can pick from a variety of fittings, including elbows, tees, flanges, and offsets, for compatibility with your system. Vertical hangers are readily available for installations where the busway is installed vertically, with a UL-compliant spacing of 16 feet between hangers to provide stability.

NEMA Fusible and Circuit Breaker Plugs for Safe Operation

Plug-in units for Pow-R-Way busways feature interlocks to prevent accidental operation. Devices including fusible plugs and circuit breaker plugs give reliable performance. A two-position handle allows flexibility for horizontal or vertical mounting, and backfeeding is supported under specific conditions .

Short-circuit bracing follows NEMA standards, so the system withstands maximum available short-circuit currents. Operating characteristics are tested to give a safe temperature rise and withstand high-voltage applications.

Standard sections of Pow-R-Way busways are available in 10-foot lengths, with special sections customized to your project needs. The system supports vertical or horizontal mounting without derating, and detailed tables for dimensions and weights are given for optimal planning.

Key Features of Pow-R-Way Busway Systems

| Epoxy Insulated Bus Bars | Provide consistent insulation along the full length of the bus bars, improving safety and reliability. |

| Joint Design with Captive Bolts | Secure connections reduce labor during assembly, improving efficiency and safety. |

| Plug-in Openings on 24-inch Centers | Allow easy installation and access for plug-in devices, improving flexibility and scalability. |

| Copper or Aluminum Bus Bars | Versatility to select higher conductivity (copper) or cost efficiency (aluminum). |

| Non-ventilated, Enclosed Design | Protects busway system from environmental factors, reliable for indoor and outdoor situations. |

| Safety Interlocks on Plug-in Units | Prevent accidental operation during maintenance, designed for personnel safety. |

| Modular Fittings and Components | Flexible to meet your installation’s needs with standardized flanges and elbows. |

| UL and NEMA Compliance | Meets industry safety and performance standards, for reliability and system compatibility. |

| Flatwise or Edgewise Mounting | Offers flexibility in mounting positions without requiring de-rating, allowing for adaptable installations. |

| High Short-circuit Bracing | Supports the system, handling high fault currents, improving safety and system protection. |

FAQ: Pow-R-Way Busway and ITAP Plugs

🟥 What are ITAP bus plugs used for?

✅ ITAP bus plugs are designed specifically for Eaton/Cutler Hammer Pow-R-Way I & II busway systems, supporting high-amperage applications. They handle up to 600 volts and are used in industrial settings requiring high electrical capacity, typically up to 200 amps.

🟥 How can I identify ITAP vs. TAP bus plugs?

✅ ITAP bus plugs have a staggered or offset stab configuration, while TAP bus plugs have an aligned stab layout. ITAP plugs are used for systems up to 4000 amps, while TAP plugs are usually for systems up to 1000 amps.

🟥 What is the design difference between Pow-R-Way II and Pow-R-Way busway systems?

✅ Pow-R-Way II busway systems are designed for 225-400 amps, featuring copper or aluminum bus bars. The Pow-R-Way systems handle up to 5000 amps and have flexibility for both indoor and outdoor use, with interchangeable fittings for different situations.

🟥 What fittings are available for Pow-R-Way busway systems?

✅ You can choose from a variety of fittings, including elbows, tees, flanges, and offsets. These fittings are standardized for compatibility across the system, giving flexible installation options.

🟥 How do safety interlocks on plug-in units work?

✅ Safety interlocks prevent accidental operation during maintenance by seeing that plug-in devices cannot be energized when the cover is open. This feature enhances personnel safety when working on busway systems.

🟥 Can Pow-R-Way busway systems be mounted vertically or horizontally?

✅ Yes, Pow-R-Way busway systems support both vertical and horizontal mounting without de-rating. Standard sections come in 10-foot lengths, with the option to customize for your project needs.

🟥 What are the key benefits of epoxy insulated bus bars?

✅ Epoxy insulated bus bars provide uniform insulation across their entire length, enhancing safety by reducing the risk of electrical faults. This insulation also improves the reliability and lifespan of the busway system.